Reefer

Waste

Tanker

Trailer

Medium Duty

Trusted By The World's Top Companies

From entrepreneurs to Fortune 500s, we’re supporting our partners as they deliver day-in and day-out.

Changing the world

one revolution at a time.

Featured News

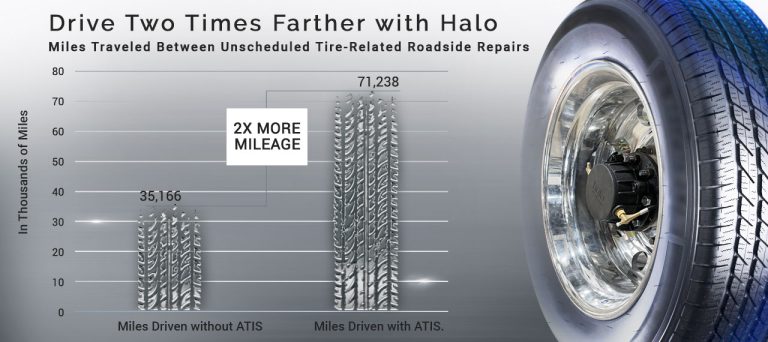

Aperia Halo® Tire Inflator Shows Fuel Savings in MVTS Testing

Foodliner

Who’s Validating ATIS and TPMS and Why Should Your Fleet Care?

Tire Health at your Fingertips

Halo Connect i3 pairs automatic tire inflation with predictive tire pressure monitoring (TPMS) to drive meaningful savings in casing life, fuel consumption, uptime, accident & service failure avoidance. Halo Connect i3 uses machine learning to alert early, not often, ensuring clients have the flexibility to address tire health issues in the most convenient and economical way possible.

Protect Your Uptime

According to an ATA benchmark study, vehicles equipped with Automatic Tire Inflation Systems (ATIS) run two times farther without experiencing tire-related downtime. Effective tire pressure management goes a long way in reducing downtime!

Environmental Impact

Installing Halos on your tires results in less diesel usage and less tire consumption. In fact, Halo delivers the most CO2 savings per dollar spent than any other truck technology available today.

Frequently Asked Questions

The best fleet tire pressure management options include Tire Pressure Monitoring Systems (TPMS), auto-tire inflation systems, and regular manual inspections. These solutions ensure tires remain at optimal pressure, enhancing safety, performance, and fuel efficiency.

Fleet tires can be managed better by implementing TPMS and auto-tire inflation systems, conducting regular inspections, and maintaining proper tire rotation schedules. Using fleet tire management software to track tire health data and trends can also aid proactive maintenance and timely replacements. Training drivers on the importance of tire care further enhances overall tire management.

Yes, truck tire pressure significantly affects fuel economy. Properly inflated tires reduce rolling resistance, allowing the engine to operate more efficiently and consume less fuel. According to industry studies, maintaining optimal tire pressure can lead to fuel savings of up to 1.4%, which is substantial for fleets covering long distances.

Lowering fleet operating costs can be achieved by implementing technologies such as TPMS and auto-tire inflation systems to maintain optimal tire pressure, thus improving fuel efficiency and extending tire life. Regular vehicle maintenance and driver training on fuel-efficient practices, combined with data analytics, optimize maintenance schedules and lead to significant cost savings.

TPMS is a system designed to monitor the air pressure inside pneumatic tires on vehicles, providing real-time information to the driver.

TPMS helps fleet managers ensure that tires are always properly inflated, which improves fuel efficiency, enhances safety, and reduces tire wear and maintenance costs.

The main benefits include increased fuel efficiency, extended tire lifespan, improved safety, and reduced risk of tire blowouts.

While TPMS can’t prevent blowouts directly, it can significantly reduce the risk by alerting drivers to potential issues before they become critical.

Factors to consider include the system’s reliability, ease of installation and use, compatibility with existing fleet technology, and the quality of customer support.

Yes, there are direct and indirect TPMS. Direct TPMS measures air pressure directly from the tire, while indirect TPMS estimates pressure by monitoring wheel speed and other vehicle data.

Properly inflated tires have lower rolling resistance, which means the engine doesn’t have to work as hard, leading to improved fuel efficiency.

Many modern TPMS solutions offer integration capabilities with fleet management software, allowing for real-time monitoring and analysis of tire pressure data across the fleet. Halo Connect i3 is an intelligent automatic tire inflation system with integrated sensors allowing for seamless data collection and reporting.

TPMS sensors generally require minimal maintenance, but they should be checked periodically for battery life and replaced as needed to ensure they remain functional.